BLIC KNOWLEDGE

Certification process

Numerous BLIC products are certified. What is the certification process and how does it work?

The certification procedure starts by sending the parts to the laboratory, where following features are examine:

- overall visual appearance of the part

- product raw material composition

- shape and dimensions in comparation to the original part

- on vehicle fitting test

- pendulum crash test to check kinetic energy absorption

- high and low temperature resistance

- moisture & salt spray test

Above listed tests are carried out by independent test institutes: Centro Zaragoza in Spain, Thatcham Research in the UK, TUV Rheinland in Germany and Capa in the USA.

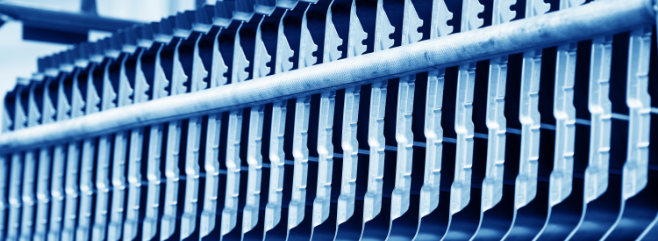

Galvanised parts

All BLIC certified metal parts are manufactured from galvanised steel.

In simplest terms, electro-galvanizing is a process in which a thin layer of another metal is bonded to steel in order to protect against corrosion. In the automotive industry, the most common method is zinc coating. The process is immersing a metal element, e.g., a wing, in the so-called galvanic bath filled with a solution of chemical compounds and pure metal, e.g., zinc. Under the influence of the flow of current and an electrochemical reaction, molecules of the solution with the dissolved metal adhere to the component, forming a permanent protective coating.

How do I recognize the quality variant from the BLIC index?

The predominance of parts in the BLIC range are those with the PC and PJ codes.

Products with the PJ code can be recognized by the letter “P” at the end of the index number, e.g., 6803-00-0066281P.

Products with the PC code can be recognized by the letter “Q” at the end of the index number, e.g., 6803-00-0066281Q.

Certified parts are also marked on the packaging and on the part itself.

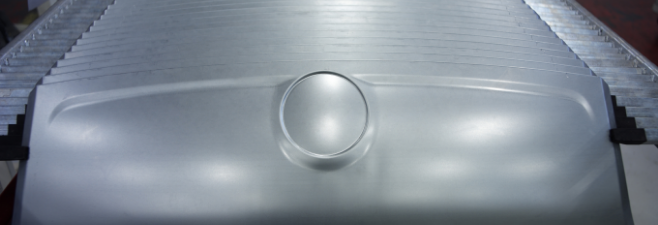

Additional protection of metal parts

All BLIC metal parts are coated with a layer of black, firmly adhering protective coating. This coating is produced by painting using the cataphoresis technique, also known as electrophoresis. This technique involves applying a paint film to electrically conductive surfaces. The purpose of painting is to protect metal parts against weather conditions during transport and storage. The advantage of such painting is that the paint reaches all the hard to reach gaps of the painted element, creating a hard and even surface.